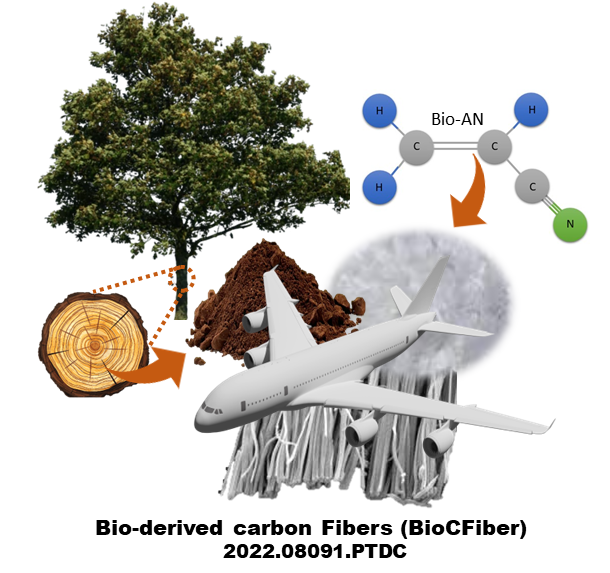

Bio-derived Carbon Fibers (BioCFiber)

Obtaining carbon fibers from renewable resources (lignin and bio-acrylonitrile) by applying innovative radical copolymerization techniques

Learn about our Goals

Description

Polyacrylonitrile (PAN) is the main raw material employed in the acrylic and carbon fibers (CFs) industries. It allows the production of high modulus CFs, with excellent properties for high performance, high strength, and lightweight composite materials. The production process involves copolymerization of acrylonitrile (AN) with other comonomers, followed by separation and drying of the polymers, its dissolution (forming the dope) and spinning. The comonomers typically used are carboxylic acids (acrylic acid, methacrylic acid and itaconic acid), amides and esters. Besides being expensive, PAN-based CFs are derived from petrochemical sources. Green technologies to achieve the highly demanded CFs from bio-based renewable starting materials are of critical relevance, since they are subjected to lower environmental impact.

Lignin is one of the most abundant biopolymers in lignocellulosic biomass. In the industry it is present as by-product of the pulp and paper industry, and cellulosic ethanol production. However, it is being treated as waste or used in low-value applications such as fuels. On the other hand, bio-acrylonitrile (bio-AN) industrial production, with high yields, is at its infancy, and there is a need for the starting of the first trials for CFs precursor production, to check whether and how bio-AN impurities from biomass affect the properties of the CFs compared to the industry standard.

The BioCFiber project targets the replacement of petroleum-based CFs by bio-based CFs. To address the challenge of the BioCFiber project, a new approach will be followed giving rise to high quality, bio-resourced CFs precursors made from new lignin-derived copolymers, obtained via free and controlled radical polymerization.

Funding

2022.08091.PTDC

FUNDING (TOTAL)

293 988,70 €

FUNDING (IST-ID)

205 988,70 €

DURATION

01.03.2023 – 28.02.2026

36 months

PRINCIPAL INVESTIGATOR (PI)

Co-PI

Prof. José G. Martinho

Goals

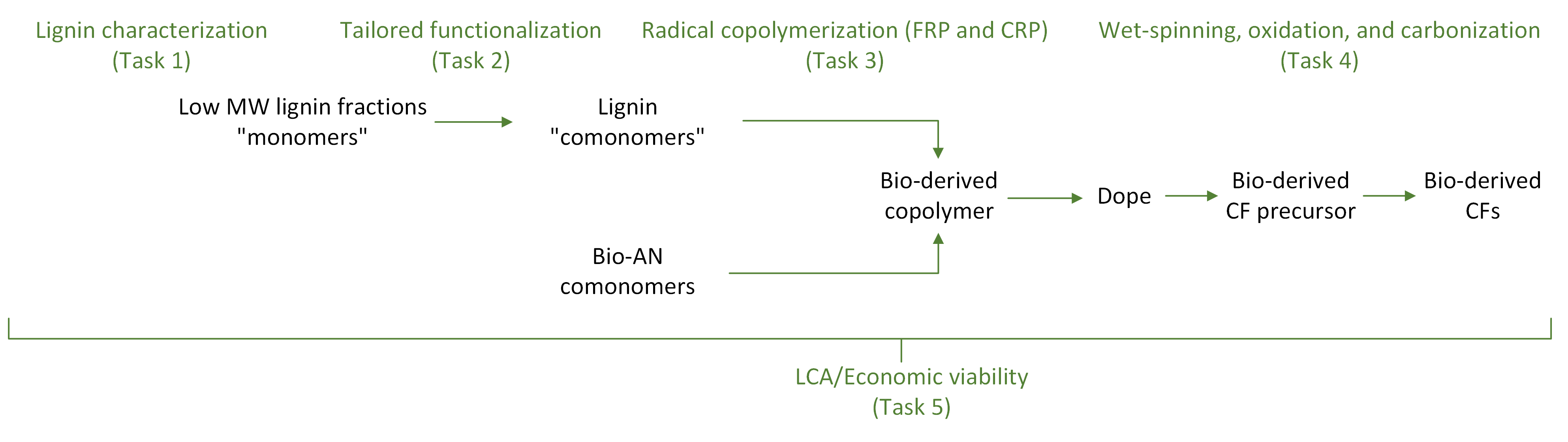

The ultimate goal of the project BioCFiber is the replacement of petroleum-based CFs by bio-based CFs. This project deals with the development of a clean and environmentally friendly technology platform for the generation of advanced green copolymers, where new copolymerization strategies will be explored, implemented and scaled-up. To address the main goal, the BioCFiber has five main secondary goals:

Design

Design of functionalization approaches of the lignin fractions. Comprehensive characterization of the comonomers, namely functionalized lignin macromolecules and bio-AN.

Wet-spinning

Preparation and optimization of the CFs precursors, by wet-spinning of the dissolved copolymer (dope) and iterative optimization of the copolymerization reactions.

Constant Analysis

Analysis of the economic feasibility of the whole process and life cycle assessment.

Methodology

This methodology, “from monomers to copolymers”, targets higher homogeneity of the resulting fibers and enhanced mechanical properties than those achieved from physical blends of lignin (polymeric) and PAN, bypassing the issues that have prevented the state-of-the-art technologies of being industrially implemented.

The BioCFiber project has a deep focus on innovation driving in what regards the lignin macromolecules functionalization and copolymerization methods with the bio-AN monomer. Advanced radical copolymerization strategies will be explored and implemented, which are the main scientific challenges and disruptive advances to the state of the art of the project. The resulting new technology platform has in mind industrially attractive and environmentally friendly pathways for lignin valorization, as well as green and cost-effective bio-derived CFs.

To address the typical gap between fundamental research and industrial product development, SGL Composites SA, a major producer of CFs precursors, is engaged and committed to participate in the BioCFiber project, bringing extensive experience and international leadership for the development of the CFs precursors. The consortium has unique competence through the complete value chain to execute the project. However, to minimize any possible risk regarding radical copolymerization and scale up, we count with a further expert on this topic, Prof. Jorge F. Coelho, as consultant. Of relevance, there is also the collaboration with RAIZ/The Navigator Company concerning the supply of large amounts of lignin fractions for the execution of the project, including the scale-up trials and potential future collaboration with IST and SGL Composites. The economic viability of the overall process as well as sustainability through LCA will be evaluated.

Results

Outputs

Available soon

Available soon

Available soon

Available soon

Partners

Researchers

IST-ID (CERENA, CQE, CEGIST): Ana C. Marques, Rui Galhano, António Aguiar, Marta Ramos Andrés, Talita Nascimento, Mónica V. Loureiro, José Paulo Farinha, J. Gaspar Martinho, Dulce Simão, José Ascenso, M. João Ferreira, M. Teresa Viciosa, Sérgio Alves, Ana Carvalho

SGL Composites: Rui Dias, Ricardo Caldas, José Figueira, Luís Vale, Pedro Borregana, Vítor Calado

Consultant: Jorge F.J. Coelho (University of Coimbra, Polysyc)